Introducing

The Aloha Sustainable materials recycling & Fertilizer Facility

(We like to call it SMRFF for short!)

What it IS

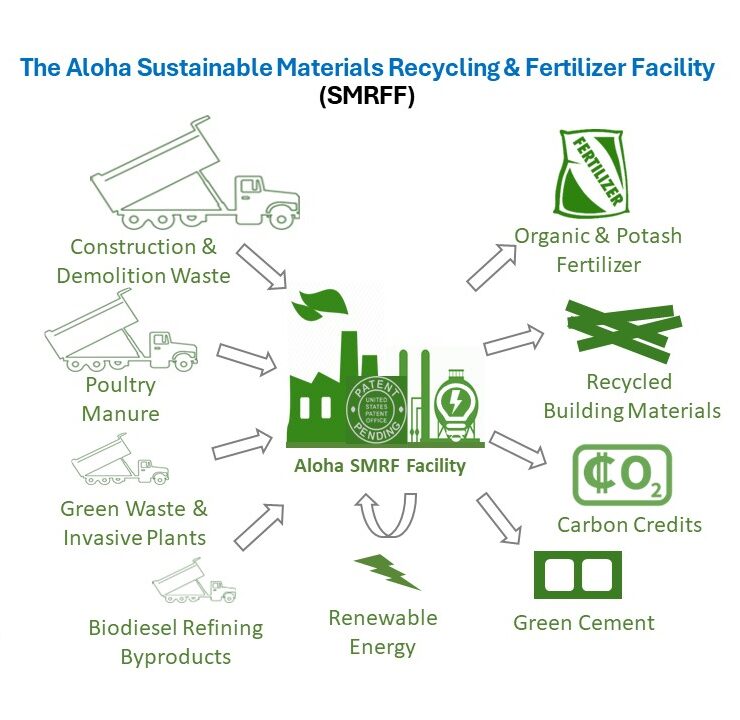

The Aloha Sustainable Materials Recycling & Fertilizer Facility (SMRFF) is a waste recycling facility under development by Simonpietri Enterprises LLC in the James Campbell Industrial Park in Kapolei, Hawaii. The facility will provide a solution for locally generated solid and organic wastes which are currently landfilled. The purpose of the facility is to divert waste from being landfilled and instead recycle as much as possible into useful products.

How it works

We plan to accept a variety of different wastes, including construction and demolition (C&D) debris, which upon receipt, would be sorted, separated and valuable materials recycled. The organic C&D components, like clean unpainted wood – along with tropical biomass and invasive species waste – will be converted into synthesis gas using a fluidized-bed gasification system, which will then be used to create electricity to help self-power the facility. The clean wood and green waste ash produced from the gasification process along with chicken manure and other wastes, will be combined to create 100% locally produced organic and potash fertilizers to support Hawaii’s agricultural industry and work towards improving food security & resiliency. The inorganic waste sorted out from the C&D debris, such as concrete and window glass, we plan to convert to recycled-material building products. With these efforts, we estimate we can divert about half of the C&D waste from O’ahu’s landfills, and we are always looking for innovations to divert even more.

The Aloha SMRFF waste inputs and product outputs

Crop trials & results to date

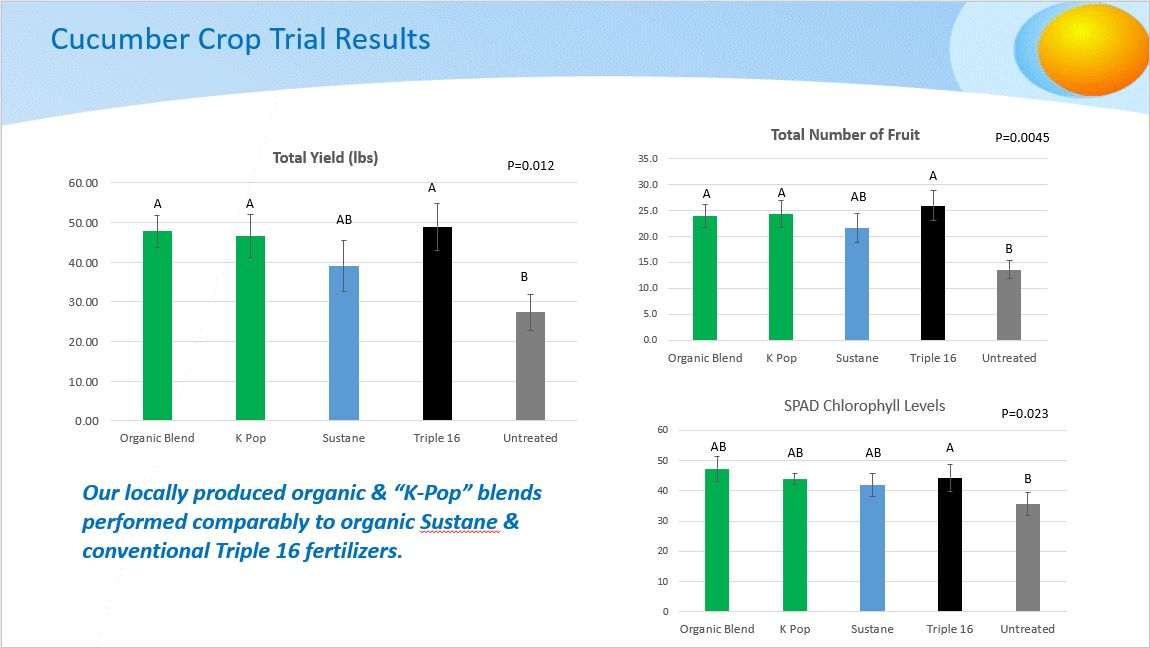

Cucumber Trial

Location: UH Waimanalo Research Station

ANOVA – Multiple data sets

Because the cucumbers produced fruit for over a month, data was gathered from multiple harvests. The results showed that our Organic & K-Pop blends produced similar yields as compared to organic Sustane and a conventional (fossil fuel derived) 16-16-16 fertilizer when it came to both weight and number of fruits yielded. Although there wasn’t a statistically significant difference between our blends and the two commercial products, there was a significant difference between plots that were treated with our blends, and the control (untreated).

Findings: Crop growth appears very responsive to our first formulations and performed statistically better than untreated plots.

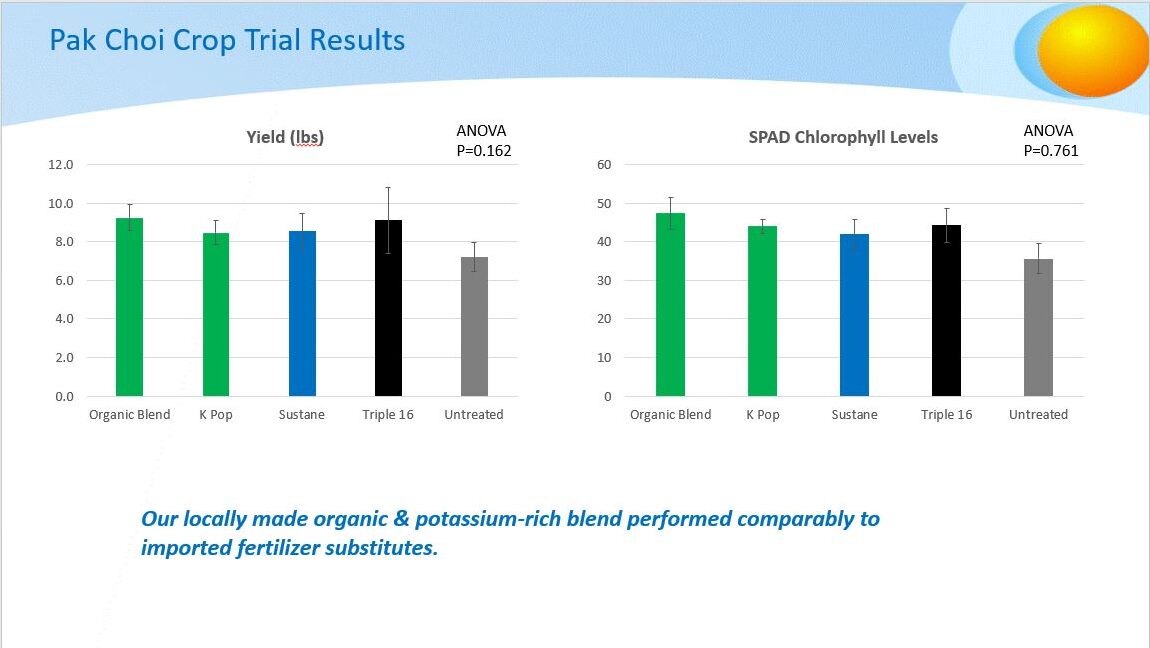

Pak Choi Trial

Location: Pearl City Urban Garden Center

ANOVA – Single harvest

The results for the Pak choi indicated there were no significant differences between the four fertilizers, and that our two blends performed slightly better than the control.

Findings: Performance of our initial formulations was comparable to imported organic and conventional fossil fuel-derived substitutes.

Key Takeaways

We were able to prove the viability of concept: we can produce fertilizer products, from 100% locally sourced waste components, which perform the same as imported commercial fertilizer products.

The Problems we are addressing

Landfilled Waste

Mixed Green Waste

Manure Management

Invasive Species

Climate Change

Environmental justice

Making Fertilizer

THE ORIGIN Story: How we came TO makE fertilizer

As part of our early community engagement efforts for making sustainable aviation fuel through the Aloha Carbon technology, we conducted dozens of stakeholder interviews and two iterations of an online survey to receive input from the community for our project design. As we described our plan to community members to convert C&D waste to renewable fuel, one of the most frequently asked questions we got in response was “can you do something about invasive species, too?” As a result, we applied for and won a U.S. Department of Energy research grant to look into using fast-growing real-world invasive tropical greenwaste and invasive plant biomass as a supplemental feed material for our gasification process. Our gasification trials showed that we could not only use this green waste as a supplemental feedstock to make fuel, but also provide100% certified destruction services for invasive plants and pests. In addition, we realized that the nutrients in the ash could be recycled to make organic and potash fertilizer ingredients, which led to this exciting opportunity.

View our presentation to the Makakilo-Kapolei-Honokai Hale Neighborhood Board in February 2024 to learn more.

locally generated wastes we have been using to make fertilizer

Wood waste

Of the 1500-2000 tons of construction and demolition that gets landfilled daily, approximately 40% is wood waste that has the potential to be recycled. Because of the challenges this waste stream presents, there are no other solutions currently available.

Wood waste from the removal of invasive trees also contribute to Hawaii’s overall wood waste.

Mixed Tropical green Waste & Invasive plants & pests

Hawaii’s landscape has become over-run with fast-growing, fire-prone invasive plants that can be highly destructive as was evidenced by the tragic wildfires in 2023 on Maui island. Additionally, there has been an increase in destruction caused by invasive pests like the Little Fire Ant (LFA) or Coconut Rhinoceros Beetle (CRB) which has been killing palm trees island-wide. Now more than ever, there is a need for a certified destruction and treatment process to stop the rapid spread of these invasive pests and plants.

Chicken Manure

Manure is the single largest limiting factor for expansion of egg-laying farms on O’ahu. We aim to address this with our proposed new Sustainable Materials Recycling and Fertilizer Facility (SMRFF) project, and convert the manure into an ingredient for USDA-compliant organic and potash fertilizer.

Biodiesel Potassium Cake

Potassium saltcake is a byproduct of the biodiesel refining process. In Hawaii, this material currently has to be disposed in a landfill. The SMRFF is being designed to recover the nutrients from this waste and manufacture potash fertilizer.

We want to hear from you!

The Environmental assessment for the Sustainable materials recycling and fertilizer facility was officially published September 23rd, 2024 and is open for comment to october 22nd, 2024. Click the link to view the publication.

Gallery